An Eleventh-Century Pittsburgh in Sri Lanka

From the seventh to the eleventh century A.D., Sri Lanka was united under the strong central administration of Sinhalese Buddhist kings. Archeologists know this as the island's Classic Period. And one of its main industries during that period, it now seems, was high-quality steel. In the iron-rich hills of southern Sri Lanka, archeologist Gill Juleff of University College, London, has discovered 77 sites where iron was worked-and in a particularly ingenious way, as she reported last Jannuaiy From excavations and experiments, Juleff has found that Sinhalese ironworkers did not have to wear themselves out pumping the bellows. Their furnaces allowed monsoon winds to fan the flames.

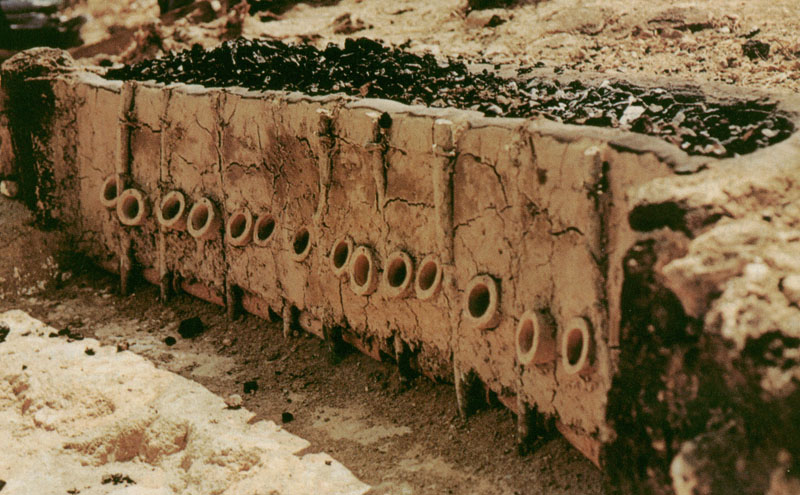

Juleff noticed that all 77 of her sites were located on west-facing slopes, exactly in the path of the fierce monsoon that blows every year from June to September. "The location gave us the first clue to some connection with the wind," she says. At one of the sites, Juleff excavated 41 furnaces. Each consisted of a clay rear wall built into the hillside in the north-south direction, approximately six feet long and less than two feet high, that curved around to meet the front wall. Toward the bottom of the front wall, a row of tuyeres, or short clay pipes, allowed air to flow into the furnace. The top was open.

Scholars had assumed that the wind, with its inconstant gusts, could never keep a fire hot enough to make iron from iron ore, let alone make iron combine with the carbon in charcoal to produce steel. But Juleff found otherwise when she smelted iron herself on a Sri Lankan hillside in a replica of the ancient furnaces. The wind, she discovered, doesn't blow directly into the furnace like a bellows; it blows over the open top, creating a low-pressure area along the inside of the front wall. This causes air to be sucked in through tuyeres at a fairly steady rate that responds only slowly to changes in wind velocity~ Juleff's furnace could easily maintain a constant temperature of 2,600 degrees Fahrenheit.

Half the metal she produced was impure iron that would have required repeated heating and hammering to make into steel. But the furnace also directly produced good-quality high-carbon steel Juleff estimates that the 77 known sites in southern Sri Lanka could have produced a total of 3,500 tons of metal, both iron and steel, during the four centuries the furnaces were in use. Some of that Sri Lankan steel, she speculates, may have been exported to Africa and the Near East, where it may have been fashioned into the legendary Damascus swords that baffled the Crusaders with their strength and sharpness.

-Shanti Menon (Discover January 1997)

Other Excerpts

How Dr. Juleff pieced this archaeological discovery together is too a tale worth relating. Researching the environmental impacts of the Samanalaweva dam with archaeologist P.B. Karunaratne and the Archaeological Department team 20 years ago, her interest was aroused by the references to iron being smelted in Samanalaweva in Ananda Coomaraswamy’s 1908 book ‘Medieval Sinhalese Art’. “When I came there first, there was no one making iron. But there were people who remembered their grandfathers talking about it,” she recalls.

The long range transmission of the Sri Lankan technological traditions of iron smelting and steel-making, in particular the development of linear furnaces, is now the focus of a new phase of research. Potential but hitherto unrecognised connections between Sri Lanka, Burma, Cambodia, Sarawak and, most significantly, Japan, have been identified in a paper in World Archaeology. Careful analysis and interpretation of the evidence has indicated strong similarities between the wind-powered furnaces of Sri Lanka and the world famous tatara furnace of Japan, in which the steel for Samurai swords was made.

http://www.nature.com/nature/journal/v379/n6560/abs/379060a0.html

http://www.nytimes.com/1996/02/06/science/ancient-smelter-used-wind-to-make-high-grade-steel.htmlhttps://humanities.exeter.ac.uk/archaeology/research/themes/materialcultureandsocialagency/projects/monsonsteel/

Contact:

Sereno: +94 77-858 4009

wilpattuHouse@gmail.com